What is a Crane Scale?

A crane scale is a specialized weighing device designed to measure the weight of suspended loads in industrial and commercial settings. These scales are typically integrated with cranes, hoists, or other lifting equipment, allowing users to obtain accurate weight readings while ensuring safety and efficiency during lifting operations. Commonly found in industries such as manufacturing, shipping, construction, and logistics, crane scales are essential tools for businesses that require precise weight measurements for operational effectiveness, compliance with regulations, and inventory management.

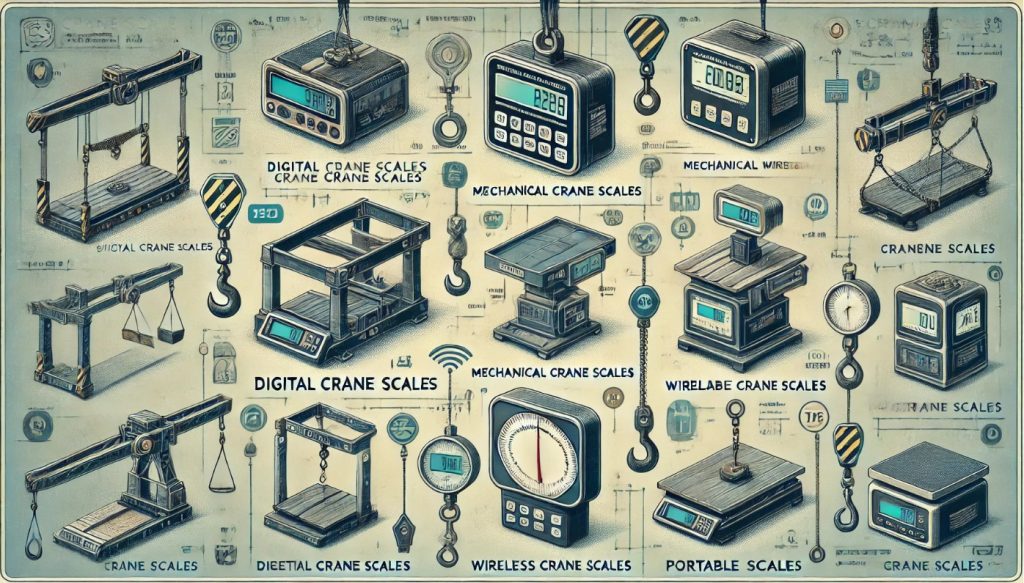

Types of Crane Scales

1. Digital Crane Scales

Overview

Digital crane scales utilize electronic sensors to provide precise weight readings displayed on a digital screen. These scales often come equipped with features such as remote displays, data logging capabilities, and connectivity options, making them highly versatile for various applications.

Advantages

- Accuracy: Digital scales offer high precision in weight measurement, ensuring reliable data for critical operations.

- Ease of Use: User-friendly interfaces and clear digital readouts enhance usability, allowing operators to quickly read and interpret measurements.

- Additional Features: Many digital crane scales include functions like tare, hold, and peak hold, which can be invaluable in complex lifting situations.

Disadvantages

- Battery Dependency: Digital crane scales typically require batteries, which necessitates regular replacements or charging, potentially leading to downtime.

- Cost: Generally more expensive than mechanical counterparts due to their advanced technology and features.

Target Audience

Digital crane scales are ideal for industries needing high precision and advanced features, such as manufacturing, logistics, and heavy-duty construction. Businesses that prioritize accuracy and technological integration will find these scales particularly beneficial.

2. Mechanical Crane Scales

Overview

Mechanical crane scales use a simple mechanical system, usually based on a spring mechanism, to measure weight. This traditional design has been in use for decades and remains popular for certain applications.

Advantages

- Durability: Mechanical scales are typically robust and less prone to failure, making them suitable for harsh working environments.

- No Power Required: These scales operate without batteries or electricity, providing a reliable solution in remote locations or during power outages.

Disadvantages

- Limited Accuracy: Mechanical crane scales tend to be less precise than their digital counterparts, which may be a drawback for operations requiring exact measurements.

- Lower Capacity: Some mechanical models may not effectively handle very heavy loads, limiting their applicability in certain industries.

Target Audience

Mechanical crane scales are best suited for smaller operations or industries where extreme precision is not critical, such as agriculture, local shipping, and certain construction applications.

3. Wireless Crane Scales

Overview

Wireless crane scales use radio frequency or Bluetooth technology to transmit weight data to a remote display or computer. This feature allows for increased mobility and convenience, eliminating the need for operators to be physically close to the scale.

Advantages

- Convenience: Operators can read weight from a distance, allowing for safer and more efficient operations, especially in busy environments.

- Flexibility: Wireless systems reduce the need for physical access to the scale, making them ideal for large warehouses and shipping yards.

Disadvantages

- Signal Interference: Wireless crane scales may experience issues in areas with high electromagnetic interference, which can disrupt data transmission.

- Cost: These scales are often more expensive than wired models due to the added technology.

Target Audience

Wireless crane scales are perfect for large-scale operations where mobility and flexibility are key, such as in shipping yards, freight handling, and large manufacturing facilities.

4. Heavy-Duty Crane Scales

Overview

Heavy-duty crane scales are engineered to handle extremely high weight capacities, often exceeding several tons. These scales are constructed with robust materials to withstand harsh industrial environments and demanding applications.

Advantages

- High Capacity: Heavy-duty scales can manage the heaviest loads, making them suitable for rigorous operations.

- Built to Last: Constructed for durability, these scales are designed to endure tough conditions, ensuring long-term reliability.

Disadvantages

- Costly: Heavy-duty crane scales come at a higher price point due to specialized materials and engineering.

- Size: These scales are typically larger and bulkier than standard models, which may affect portability and installation.

Target Audience

Heavy-duty crane scales are ideal for industries such as construction, mining, and heavy manufacturing, where massive loads are a routine part of operations.

Market Insights

Manufacturing in China

Approximately 70% of crane scales are manufactured in China. The country has become a global hub for manufacturing due to its low production costs, advanced technology, and efficient supply chains. Chinese manufacturers offer a wide variety of crane scales, making it easier for retailers and wholesalers to find products that meet their specific needs.

Cost Distribution of Crane Scales

Understanding the cost distribution of crane scales can help retailers and wholesalers make informed purchasing decisions. The breakdown is typically as follows:

- Materials: 40% of the total cost is attributed to the materials used in manufacturing the scales, including metals, electronics, and components.

- Labor: Approximately 30% of the cost goes towards labor, encompassing the skilled workforce involved in production.

- Technology/Components: Around 20% is dedicated to technology and components, such as sensors, displays, and wireless systems.

- Logistics and Overhead: The remaining 10% covers logistics, shipping, and overhead costs associated with running the manufacturing operations.

About TangScale: Your Trusted Crane Scale Manufacturer

Customization Services

At TangScale, we recognize that different businesses have unique requirements. Our customization services allow us to tailor crane scales to meet specific client needs, including load capacity adjustments, display options, and integration with existing systems.

Successful Story

One of our notable success stories involves a major logistics company that needed scales capable of weighing oversized loads for their operations. By collaborating closely with the client, we developed a custom solution that increased their operational efficiency and significantly enhanced client satisfaction. This tailored approach not only fulfilled their immediate requirements but also positioned them as a leader in their market.

Private Label Services

We offer private labeling for retailers seeking to market crane scales under their brand name. Our private label services include complete packaging design, branding integration, and support throughout the product launch process.

Successful Story

A prominent retailer approached us to create a private label line of crane scales. We assisted them in developing a range of products that quickly became their best sellers. This collaboration not only boosted their revenue but also increased their market share in the industrial equipment sector, demonstrating the effectiveness of our private label services.

ODM (Original Design Manufacturer) Services

Our ODM services provide comprehensive design and manufacturing support for clients looking to develop new products without the need for extensive design resources. This option allows businesses to leverage our expertise in bringing innovative solutions to market.

Successful Story

A startup in the weighing equipment industry collaborated with TangScale to design an innovative crane scale that incorporated unique features tailored to their target market. Our expertise in product development helped them navigate the complexities of bringing their product to market successfully, establishing their brand in a competitive landscape. This partnership not only resulted in a successful product launch but also fostered a long-term relationship between our companies.

White Label Services

TangScale also offers white label options, allowing businesses to sell our existing products under their brand without customization. This service is ideal for retailers and wholesalers looking to expand their product offerings quickly.

Successful Story

A leading wholesaler took advantage of our white label crane scales, integrating them into their catalog. The established reputation for quality associated with TangScale products led to a significant increase in their sales. This success story illustrates how our white label services can help businesses enhance their product range while focusing on their marketing strategy and customer engagement.